Introduction

Liquid sulphur dioxide (SO₂) is a colourless, pungent gas that, when compressed, can be stored as a liquid. It has various industrial applications, including in the production of sulphuric acid, in food preservation (as a preservative), and in the beverage industry for sterilisation. It is also used in the paper and pulp industry for bleaching purposes, as well as in water treatment and some chemical processes. Due to its wide range of uses, the demand for liquid sulphur dioxide continues to grow, presenting a lucrative business opportunity. This liquid sulphur dioxide manufacturing plant project report offers a detailed roadmap for setting up a manufacturing facility for this chemical, covering market demand, raw materials, production processes, equipment requirements, safety regulations, and financial considerations.

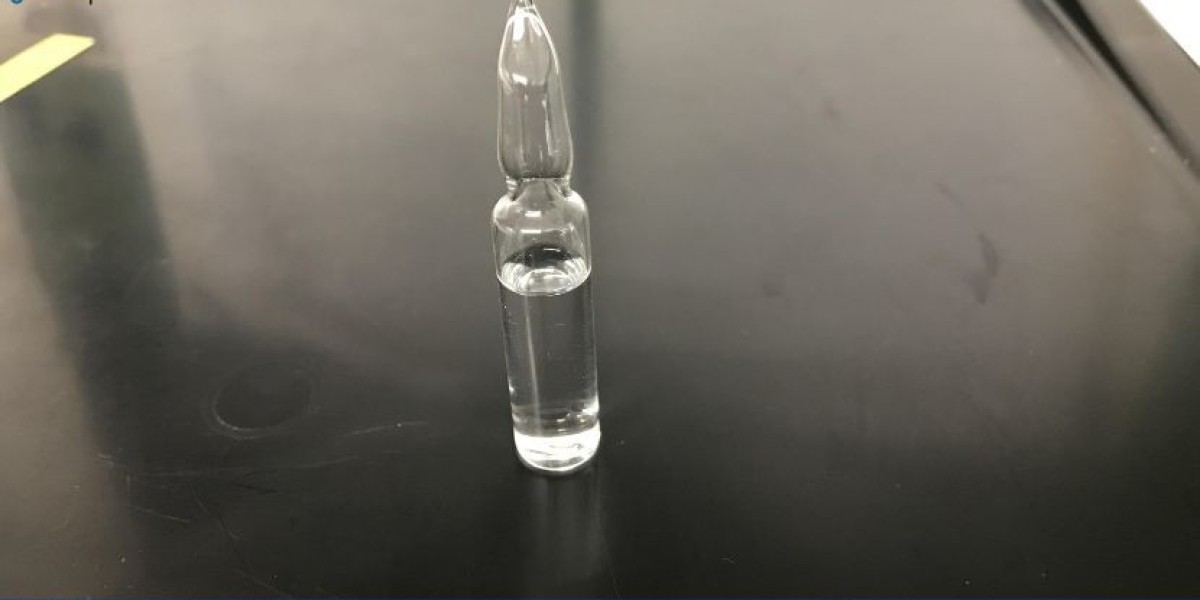

Overview of Liquid Sulphur Dioxide

Sulphur dioxide (SO₂) is typically a gas at room temperature but can be compressed into a liquid form when stored under pressure or at low temperatures. Liquid sulphur dioxide is used extensively in various industrial applications, including:

- Production of sulphuric acid: It is a key intermediate in the manufacture of sulphuric acid, a vital chemical used in many industries.

- Food preservation: Used as a preservative, especially for dried fruits and in wine production to inhibit bacterial growth.

- Water treatment: Utilised for dechlorinating water in municipal systems.

- Pulp and paper industries: In the bleaching process of wood pulp.

Market Demand and Opportunities

The demand for liquid sulphur dioxide is primarily driven by industries like chemicals, food and beverage, water treatment, and paper manufacturing. As these sectors continue to expand globally, the need for efficient and high-quality sulphur dioxide manufacturing also rises. Specifically, the food and beverage industry’s increasing use of sulphur dioxide for preservation and sterilisation provides a significant growth opportunity for manufacturers.

Get a Free Sample Report with Table of Contents@

Raw Materials Required for Manufacturing Liquid Sulphur Dioxide

The primary raw material for producing liquid sulphur dioxide is elemental sulphur, which is abundant and relatively inexpensive. The production process also involves oxygen, which reacts with sulphur to form sulphur dioxide gas. Other chemicals and catalysts are used depending on the method of production. The general process involves:

- Sulphur combustion: Sulphur is combusted with oxygen at high temperatures to form sulphur dioxide gas.

- Compression: The sulphur dioxide gas is then cooled and compressed to form liquid sulphur dioxide, which can be stored and transported in specialised tanks.

Production Process of Liquid Sulphur Dioxide

The production of liquid sulphur dioxide involves two main steps:

- Sulphur combustion: Sulphur is burned in an oxygen-rich environment to produce sulphur dioxide gas (SO₂). This reaction typically occurs at temperatures between 1000-1200°C.

- Cooling and Compression: The sulphur dioxide gas is cooled and compressed into a liquid form. The gas is first passed through a cooling system to reduce its temperature and then compressed using a mechanical compressor until it becomes liquid. The liquid sulphur dioxide is then stored in specialised tanks under pressure.

Equipment Required for Manufacturing Liquid Sulphur Dioxide

The following equipment is essential for setting up a liquid sulphur dioxide manufacturing plant:

- Sulphur combustion chamber: For the burning of sulphur in the presence of oxygen.

- Cooling system: To cool down the sulphur dioxide gas to facilitate its compression into liquid form.

- Compressor units: To compress the sulphur dioxide gas into liquid form under high pressure.

- Storage tanks: Specially designed tanks capable of handling and storing liquid sulphur dioxide safely under pressure.

- Piping and valves: For the transportation and control of the gas and liquid throughout the production system.

- Safety and monitoring equipment: To ensure the safe operation of the plant and compliance with environmental and safety regulations.

Regulatory and Safety Considerations

The production of sulphur dioxide is subject to strict environmental and safety regulations. This includes:

- Air quality standards: Sulphur dioxide emissions must be controlled and meet local and international air quality standards.

- Occupational safety: Workers in the plant must be protected from exposure to sulphur dioxide, which is toxic at high concentrations. Proper ventilation, safety gear (e.g., gas masks, protective clothing), and regular safety training must be in place.

- Storage and handling: Liquid sulphur dioxide must be stored in specialised, pressure-resistant tanks. The handling and transportation of this chemical require strict safety protocols to prevent leaks or accidents.

Market Trends and Future Growth

The global demand for liquid sulphur dioxide is driven by its use in industries such as chemicals, food preservation, water treatment, and pulp and paper production. In particular, the food and beverage industry is expected to see continued growth, particularly in the wine and dried fruit segments, where liquid sulphur dioxide is commonly used for sterilisation and preservation. As the global market for chemicals and environmental management continues to grow, the need for reliable and efficient liquid sulphur dioxide manufacturing plants is anticipated to rise, offering opportunities for growth and expansion.

FAQ

What are the primary uses of liquid sulphur dioxide?

Liquid sulphur dioxide is mainly used in chemical production, food preservation, water treatment, and the pulp and paper industry.What raw materials are needed to manufacture liquid sulphur dioxide?

The primary raw materials are elemental sulphur and oxygen. Other chemicals may be required depending on the production process.How is liquid sulphur dioxide produced?

It is produced by combusting sulphur in oxygen to form sulphur dioxide gas, then cooling and compressing the gas into liquid form.What equipment is needed for manufacturing liquid sulphur dioxide?

Essential equipment includes a sulphur combustion chamber, cooling system, compressors, storage tanks, and safety and monitoring devices.What are the safety considerations in manufacturing liquid sulphur dioxide?

Workers must be protected from toxic exposure, and emissions should meet environmental standards. Proper storage and handling procedures are crucial for safety.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au